Connector Overview and Selection Guide

Good connectors and connections can be the difference between spending your adventure on adventuring versus troubleshooting why your fridge won't turn on and racing against your ice cream turning to soup. Nobody likes melted ice cream or wasting a vacation on avoidable breakdowns.

A large variety of electrical connector options are available for building the auxiliary electrical system in your vehicle. This guide is an introduction and overview of some of the most common connector types, their benefits and disadvantages as well as our recommended uses for each type. If something isn't listed here it just means that we don't have strong opinions about them one way or the other.

Selecting a connector to use

Listed below are some of the considerations you should take into account before selecting a connector. Note that a connector ideal for one situation might be entirely unusable (or total overkill) in another. It is likely that you will use several connector types when building out your auxiliary electrical system. Some of these choices come down to personal preference such as whether to use Anderson Powerpole or SAE connectors. As a general rule, you get what you pay for here - cheap connectors and tools usually result in cheap connections.

Safety First

- Is the connector certified or designed to UL and/or IEC standards

- Is the connector composed of materials that specifically list a UL 94 flammability rating

- tl;dr - if something bad happens, will it burn or just go out after a few seconds?

- Does the connector have ratings of any kind?

- Many products available on sites such as Amazon do not provide any ratings!

- The best place to find this information is the manufacturer's website. Search for a product's "datasheet" if it's not listed directly on the product page. If in doubt, send them a message!

Electrical

- How much current will the connection need to carry, both on the input and on the output(s)

- The voltage of the circuit

- How many connections need to be made at that point in the circuit

- Whether the connector is for power or analog/digital signals that require an extremely high quality connection

Mechanical

- What gauge cable or wire will be used, both on the input and the output(s)

- What environment the connection will be exposed to

- Will it be exposed to or submerged in water

- Is oil or other fluid contamination a possibility

- Dust or mud exposure

- Temperature of the area where the connector will be installed

- Whether special tools are required to install the connector

- How often will the connection be made or broken (how often you will plug it in or disconnect it)

- How much space is available for the connector and cables

- How much clearance is required to make and break the connection

- How many connections need to be made at that point in the circuit

- How the connector will be mounted (if required)

Types of electrical connectors

Cable Lugs, Ring Terminals, Butt Splices and other Crimped Connectors

When made properly with high quality materials and tools this connector type provides a waterproof and vibration resistant connection. Almost all OEM connections in your vehicle are a variation of this type.

Here's the catch though, making these connections properly requires special tools and can be quite difficult with heavier cable gauges. Poor quality tools almost always fail to make a good connection and high quality tools for large cable gauges can be quite expensive for something you are only going to use a handful of times when building your electrical system.

While it isn't possible to fully eliminate crimped connections from any auxiliary electrical system, Tesota Overland recommends minimizing the use of crimped connectors. Where they are unavoidable we recommend using professionally manufactured cables for 8 AWG or larger cables. For size 10 AWG and smaller, using a ratcheting crimp tool and marine grade connectors is usually sufficient to ensure a reliable connection. If you decide to DIY >10 AWG cables, a high quality hydraulic crimp tool and correctly sized dies are strictly required. We do not recommend using "bolt cutter" style crimp tools on heavy gauge cables as they typically produce extremely poor connections. Marine grade heat shrink should be installed over the body of a bare cable lug and the cable insulation before final installation in your vehicle to provide electrical insulation and strain relief.

Recommended uses

- Start and auxiliary battery connections

- MRBF fuse block connections

- Battery disconnect switches

- Under hood, on frame and other exterior wiring where water and dust exposure is likely

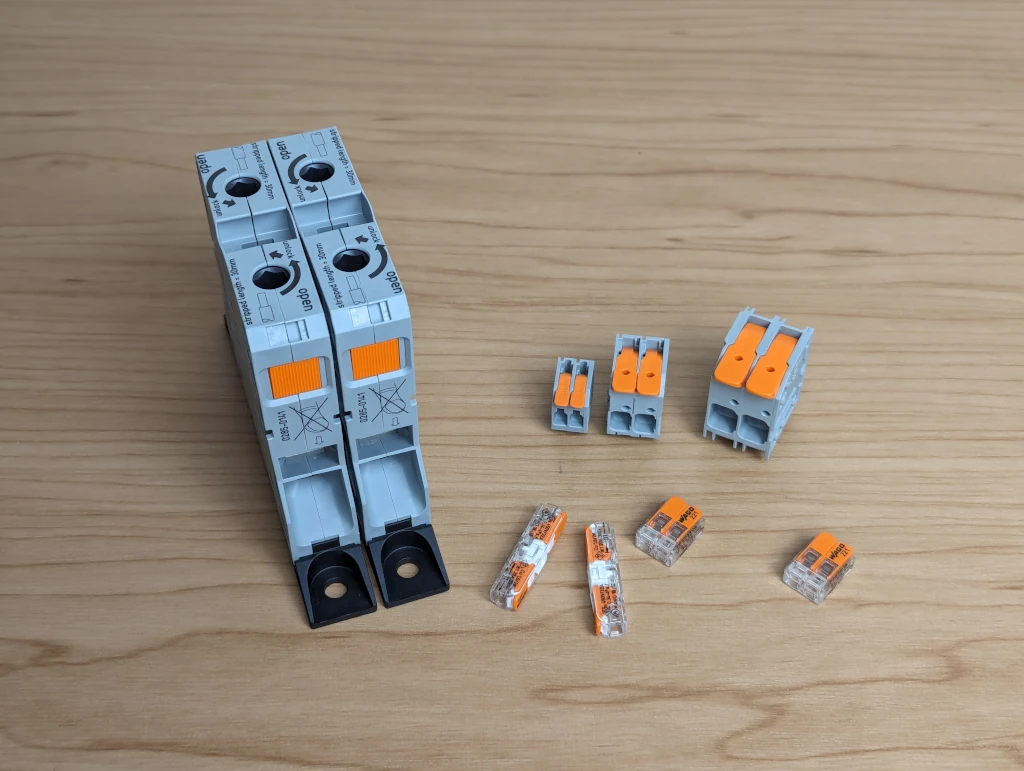

Wago and other lever type terminals

Wago connectors and terminal blocks use the Wago Cage Clamp mechanism. This connection type provides a mechanically reliable, low resistance as well as tool free option when water resistance is not a requirement. All Tesota Overland power distribution products use Wago connectors for all connections 75A or less in order to make your auxiliary electrical system installation as simple and painless as possible.

The Wago 221 series is an excellent choice for making connections between 2 and 5 wires of size 10 to 24 AWG. Mounting carriers are available for a clean installation.

For heavier gauge connections, Wago manufactures a variety of flange and DIN-rail mount terminal blocks.

A large number of manufacturers have begun producing lever style terminal blocks and connectors of varying quality and internal mechanisms. We recommend using genuine Wago products and avoiding generic knockoffs.

Recommended uses

- Interior lighting circuits

- Interior power outlet circuits

- Interior wiring butt splices (i.e. extending existing wire runs)

- Splicing into interior vehicle wiring

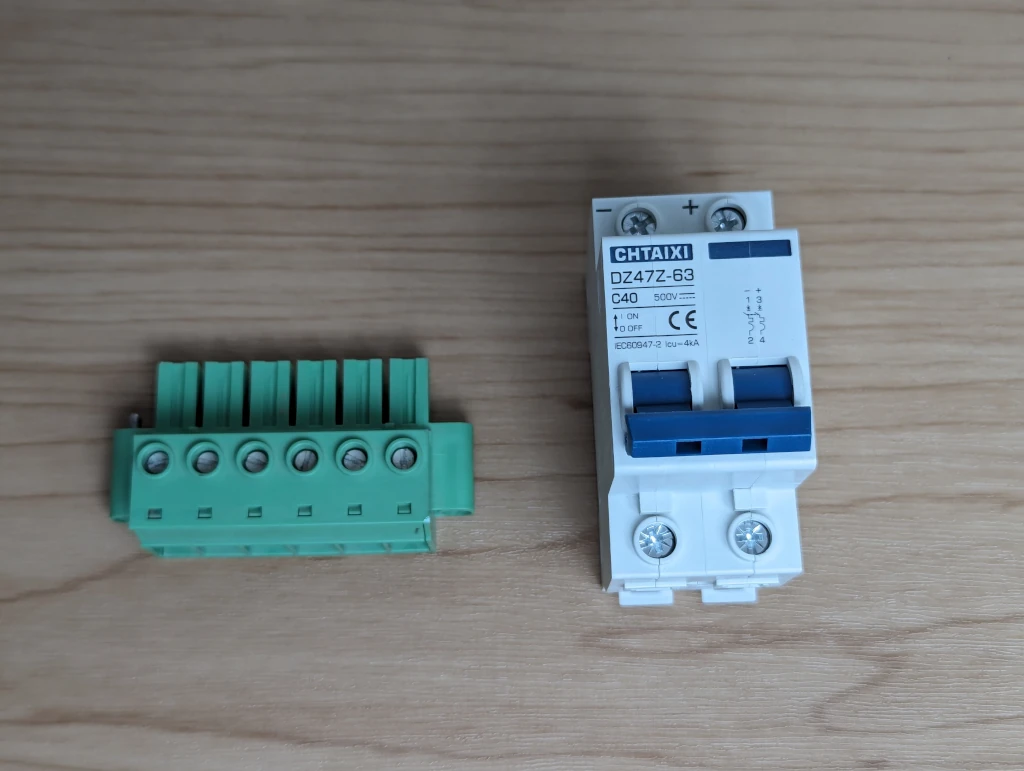

Screw type terminals

Commonly used for connections to PCBs and equipment. Each connector usually only accepts a small range of wire sizes - wires and cables that are either too small or too large will not produce a reliable connection.

Tesota Overland does not recommend the use of these connectors if other options are available. If other options are not available, such as when terminals are directly attached to equipment (Redarc Alpha, solar disconnect switches, etc), we strongly recommend including checking and re-tightening these connections to your routine vehicle maintenance.

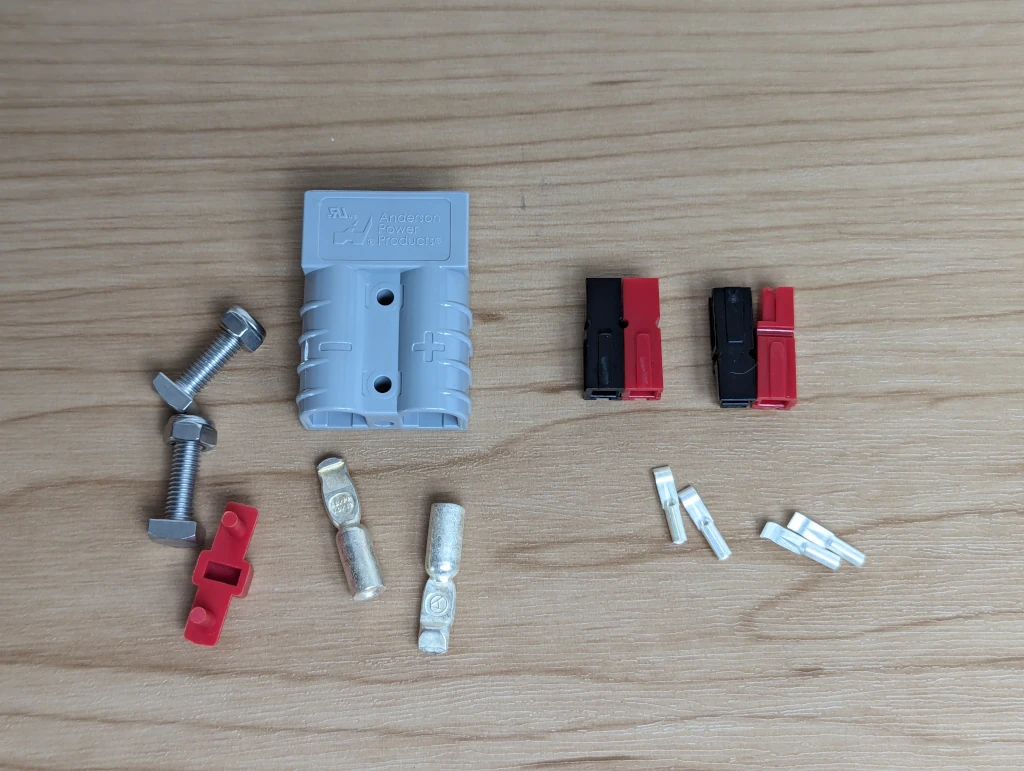

Anderson Powerpole

Typically used for connections that need to be made and broken frequently, such as for solar blankets and auxiliary battery connections to trailers. While not fully waterproof these are still used in applications where water and dust intrusion is likely. The connectors are self cleaning, highly durable, and available in sizes from from 15A to 180A.

The main drawbacks of Powerpole connectors are cost and the need for special crimp tools.

Recommended uses

- Any connection that will be frequently made and broken, both interior and exterior

- 12V battery connections for trailers

- 12V power outlets

- Very commonly used for power connections to amateur radio equipment

Automotive auxiliary power plug (cigarette lighter socket)

This is the standard 12V plug used for equipment in automotive applications. Marine versions which can lock into an outlet exist to prevent inadvertantly disconnecting equipment.

12V outlets can be useful to provide flexibility if you have infrequently used or shared equipment but are otherwise not recommended for general use. Tesota Overland recommends removing these connectors when equipment comes with them preinstalled and either replacing them with Anderson Powerpoles, SAE connectors, or hard-wiring the equipment to your APDS or fuse block.

Deutsch

Specifically designed to provide an exceptionally high quality connection where dust, moisture and other environmental factors are a concern. These connectors carry the highest IEC rating of IP69K and will stand up to just about any conditions. The primary disadvantages are cost, the need for special tools, relatively low current rating for most Deutch connectors, and a low connection cycle rating (how many times you can make and break the connector before failure).

Recommended uses

- Rear/front facing cameras

- External lighting connections (e.g. camp lights, chase/reverse lights)

- Any low-current external application where the connector will not be frequently disconnected

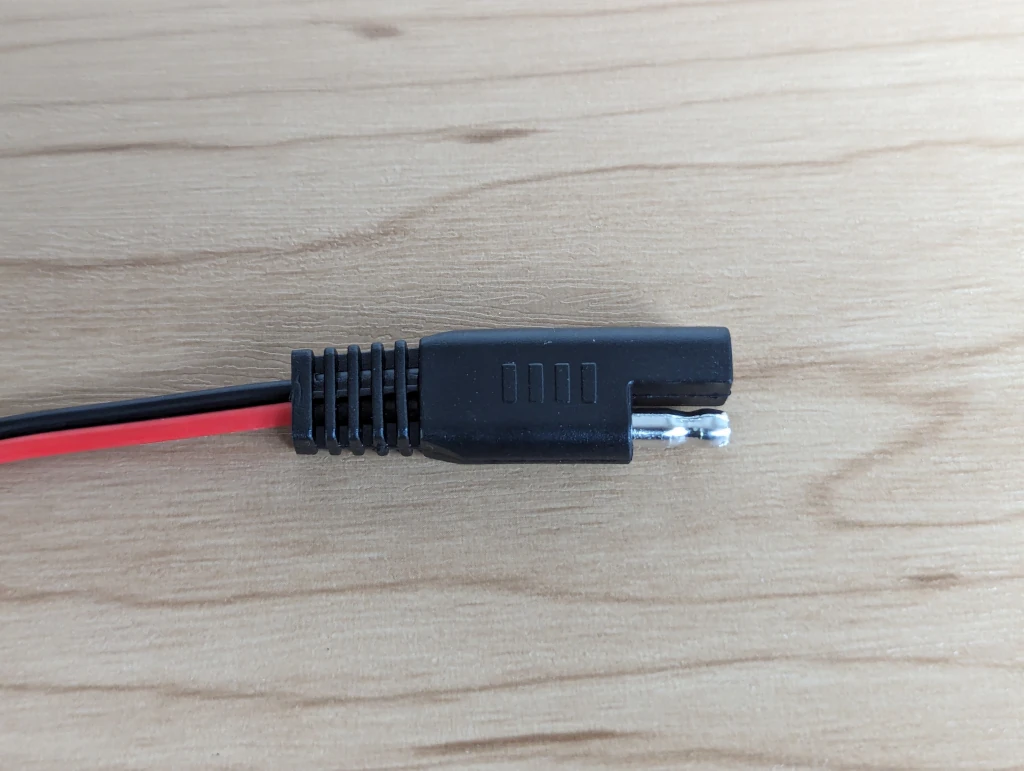

SAE (J928/J1239)

Technically only based on the SAE specifications, commonly used for both solar connections and general 12V automotive applications similarly to Anderson Powerpoles. Connectors are available from many different manufacturers and are quite inexpensive. Unlike other connector types, the SAE connector has an overmolded plastic body which is not possible to make with hand tools. Connectors are sold as pigtails which require a butt splice to connect to equipment or longer cable runs.

Note that polarity (positive and negative sides) on all connections and equipment must be verified manually. Polarity adapters may be required to connect equipment from different manufacturers.

Recommended uses

- Any connection that will be frequently made and broken, both interior and exterior

- Connections to solar panels and arrays

Solar PV (MC4)

These are the standard connectors that typically come on solar panels and other solar equipment but aren't generally used for other types of equipment. Making connections between preinstalled connectors is as simple as plugging them together, however disconnecting them requires a special tool (and should never be done under load). Special crimp tools are also required to install the connectors.

If your equipment comes with these connectors preinstalled there's not much reason to cut them off and use something else like a SAE or Powerpole connector, particularly if you have a permanently mounted multi-panel solar array.

T-Tap

Typically used to splice into existing wiring in a vehicle. T-Taps can cause extensive damage to the wires they are connected to and are a frequent source of problems and failures. Tesota Overland does not recommend using T-Taps. Posi-Taps may be an alternative when a professionally manufactured wiring harness is unavailable and cutting the wire and using a Wago 221 isn't an option.

Solder

Soldered connections should never be used for connections to stranded wire and cable when vibration resistance is a requirement. Solder will wick up the conductor which makes it brittle and prone to failure.

Wire Nuts

Exclusively made for applications where vibration resistance is not a requirement. Wire nuts should never be used for making connections in a vehicle.